Key Advantages of Industrial Automation

- Mohammad Kassim

- Nov 24

- 3 min read

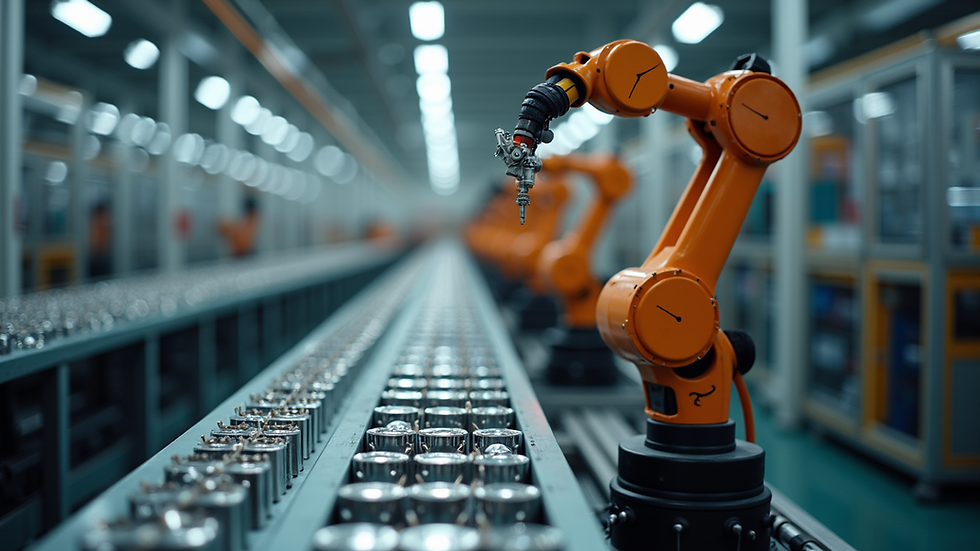

Industrial automation transforms how businesses operate by integrating advanced technologies into manufacturing and production processes. This shift improves efficiency, reduces costs, and enhances product quality. I will explain the key advantages of industrial automation and how it supports digital transformation goals.

Increased Productivity and Efficiency

Automation systems perform repetitive tasks faster and more accurately than humans. Machines operate continuously without fatigue, leading to higher output levels. For example, automated assembly lines can produce thousands of units per hour, far exceeding manual production rates.

Automation also reduces downtime. Sensors and control systems detect issues early, allowing for quick maintenance and minimizing production halts. This continuous operation maximizes resource utilization and shortens lead times.

Practical recommendations:

Implement programmable logic controllers (PLCs) to automate routine tasks.

Use real-time monitoring tools to track machine performance.

Schedule predictive maintenance based on sensor data to avoid unexpected breakdowns.

Cost Reduction Through Automation

Automating industrial processes lowers operational costs in several ways. First, it reduces labor expenses by minimizing the need for manual intervention. Second, automation decreases material waste by improving precision and consistency.

Energy consumption also drops because automated systems optimize machine usage and reduce idle time. Over time, these savings offset the initial investment in automation technology.

Examples of cost-saving measures:

Replace manual packaging with automated packaging machines.

Use automated quality control systems to reduce defective products.

Integrate energy management systems to monitor and control power usage.

Enhanced Safety and Compliance

Industrial environments often involve hazardous tasks. Automation removes workers from dangerous situations by handling risky operations such as heavy lifting, toxic chemical handling, or high-temperature processes.

Automated systems also ensure compliance with safety standards by maintaining consistent operating conditions and documenting process parameters. This reduces the risk of accidents and regulatory violations.

Actionable steps:

Deploy robotic arms for tasks involving heavy or hazardous materials.

Install safety sensors and emergency stop mechanisms.

Use automation software to log safety checks and compliance reports.

Improved Product Quality and Consistency

Automation enhances product quality by eliminating human error and maintaining strict process control. Machines follow programmed instructions precisely, ensuring uniformity across production batches.

Automated inspection systems detect defects early, preventing faulty products from reaching customers. This leads to higher customer satisfaction and fewer returns.

Recommendations for quality improvement:

Implement vision systems for real-time defect detection.

Use automated calibration tools to maintain equipment accuracy.

Standardize production processes through automation to reduce variability.

Scalability and Flexibility in Production

Automation systems can be scaled up or down quickly to meet changing demand. Adding or reprogramming machines allows businesses to adjust production volumes without extensive retraining or hiring.

Flexible automation supports multiple product variants on the same line, enabling customization without sacrificing efficiency. This adaptability is crucial for responding to market trends and customer needs.

Tips for scalable automation:

Choose modular automation components that can be expanded.

Use software-based control systems for easy reconfiguration.

Train staff on managing automated systems to handle product changes.

Leveraging Industrial Automation Benefits for Digital Transformation

Integrating automation is a critical step in digital transformation. It provides the foundation for advanced technologies like digital twins, IoT connectivity, and data analytics. These tools offer deeper insights into operations and enable smarter decision-making.

For businesses in the Middle East aiming to embrace digital transformation, partnering with local experts ensures tailored solutions that align with regional market conditions and regulations. Exploring industrial automation benefits can guide companies toward efficient and effective implementation.

Preparing for the Future with Automation

Adopting industrial automation positions businesses for long-term success. It creates a competitive advantage by improving operational agility and reducing costs. As technology evolves, automation systems will integrate more AI and machine learning capabilities, further enhancing performance.

To stay ahead, companies should:

Invest in employee training for automation technologies.

Continuously evaluate and upgrade automation infrastructure.

Collaborate with technology partners to access the latest innovations.

Automation is not just a tool for today but a strategic asset for future growth.

By understanding and applying these key benefits of automation, businesses can achieve significant improvements in productivity, cost efficiency, safety, quality, and flexibility. This foundation supports broader digital transformation efforts and helps organizations meet their objectives effectively.

Comments